Working Principles of Fabric Duct

Fabric ducts are designed to distribute cold or hot air into the area. This can be done in various ways, depending on the application. With its expertise in ventilation, our company proposes specific solutions for the projects.

In galvanized duct applications, air currents occur in some parts of the building. When people's increasing demands for comfort is taken into account, these classical solutions are insufficient. Textile duct options provide homogeneous and perfect air distribution at this point.

Fabric duct applications offer more economical solutions than conventional galvanized ducts and also increase comfort in the environment where they are applied by providing much higher quality air distribution. Fabric ducts also contribute to the architectural structure of the space with various shape, color and logo options.

Our fabric ducts are the right choice in places where a draft-free and comfortable working environment is demanded. As Havak, we offer more economical, flexible, aesthetic and practical fabric duct solutions instead of classical duct applications.

Fabric duct applications provide a comfortable environment without creating air drafts and contribute to the productivity of users and employees. Studies show that with the improvement of indoor air quality in schools, the learning ability of students increases up to 18%.

Why Fabric Channel ?

Even&Comfortable

Even&Comfortable

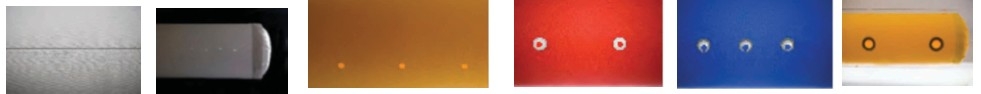

NanoSox system disperses airflow through fabric permeation and designed multi- row orifices to form a tridimensional air dispersion effect with great comfort, overall even airflow and precise air throw.

Aesthetic

Aesthetic

Multiple colors are available to blend well with any indoor decoration, Meanwhile, the system as well as the color could be customized and individually designed.

Condensation Free

Condensation Free

Air dispersion through fabric permeation forms a cooling air layer around the duct surface so that there is no temperature difference between inside and outside, therefore no insulation is required to prevent condensation.

Hygienic and Healty

Hygienic and Healty

Owing to the convenient dismantle and quick installation, NanoSox system is very easy to clean, Improved IAQ meets higher healthy and hygienic requirements

Quiet

Quiet

NanoSox system uses flexible material operating at lower air velocity, it does not generate noise or transmit resonance. Quiet system improves the indoor environmental quality.

Light Weight

Light Weight

The Nanosox™ Fabric Air Duct System is 1/40th lighter than conventional metal ductwork. The Nanosox System is often preferred in new construction and in work where ceiling load is not required

Quick Installation

Quick Installation

Specialized cable and track suspension systems bring you quick installation and reduce material waste on the jobsite. Installation time is substantially shortened, accounting g only 1/10 or less time of that of metal duct system.

Reliable Quality

Reliable Quality

Introducing large laser production line and system simulation platform into production process, all products are manufactured in our factory to ensure high pressure resistance, micro-permeability and provided to our customers with ISO 9001 Quality Management System.

Green

Green

Introducing environmental-friendly fabric, green manufacturing process, quick installation and simple operation procedure, convenient transportation, storage and recycle plus tridimensional and laminar air dispersion model makes Nanosox system greener and more energy-saving.

Economics

Economics

Simpler design of Nanosox could replace the whole traditional ductwork including air ducts, air dampers, diffusers and insulation materials, light weight, easy transportation and quick installation to reduce overall cost.

What is the advantages

High-Quality Nanosox-N, ideal Nanosox-L series and top fireproof Firesox series with variations of regular, antistatic and anti-microbial functional properties. Totally 9 products with multi-functional customization ability as per special demands, providing the most comprehensive standard permeability choices, to fulfill the higher requirements in various industries.

Nanosox - N Series Nanosox -L Series Fibersox Series

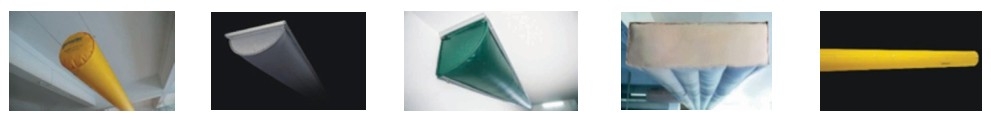

Complete Duct Profile

Besides the duck shapes of round d, half-round d, Large half- round quarter and rectangular, conic duct has been developed as the World unique, providing better air distribution performance and economic features.

Round-O Half Round-O Quarter Round-O Rectangle Conic

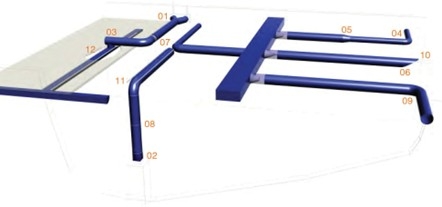

Versataile Fittings

In addition to regular fittings ( inlet, end cap, elbow, T connector ), Unique fittings such as square to round, Y inlet, bevel end cap, tension ring, wall pass-through and expansion segment and more are introduced to fit various applications.

Outlets

Airflow can be discharged through fabric permeation, mesh slot, s-slot, lineer slot, orifice, nozzle and rings.

Premium Fabric Material

Unique micro of permeability technology

Permeability as low as (3,6 m3/m2/h ) can be achieved to ensure minimum air permeation in high pressure large systems, while still maintaining condensation free.

Superior fire resistant Nanosox

The superior fire resistance performance of Nanosox does not degrade after repeated laundering.

Nonflammable Firesox Material

Nonflammable Firesox is made of non-organic fireproof material. It is classified under nonflammable as Class A type, to meet stringent fire safety requirement.

Best Industry Warranty

Exceptional product series are backed by an unmatched industry warranty. 15 years, 10 years and 8 years limited warranties come with Nanosox-N, Nanosox-L and Firesox series.

Professional Desing and Installation

World leading air dispersion system technology

With a large space airflow lab and modern CFD computer simulation technology, Nanosox engineers can tackle the most complicated and most demanding project with precision and confidence.

Detailed design manual and iCase application gallery

Accompanied by thousands of clients iCase application gallery, the new Nanosox system design manual is easy to follow and easy to find reference project designs to achieve optimum solutions.

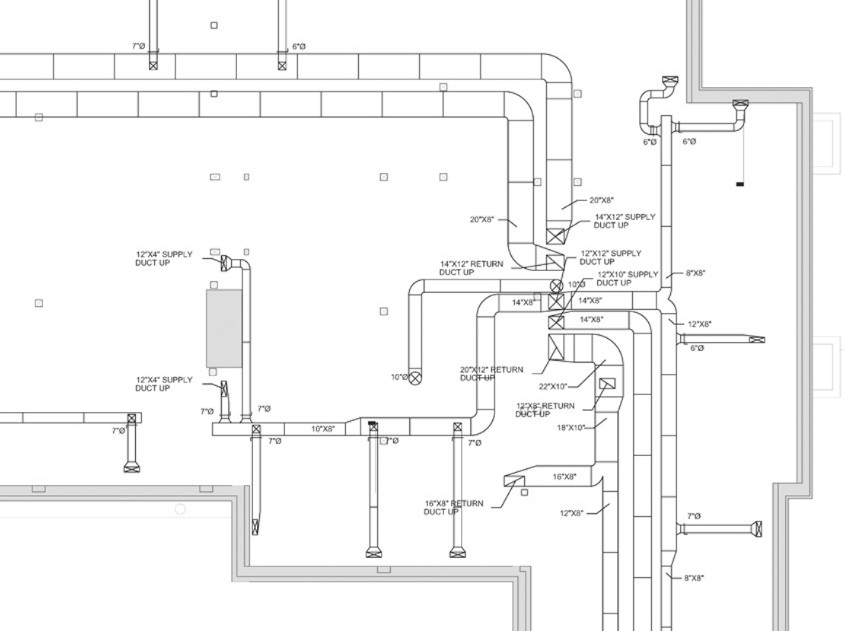

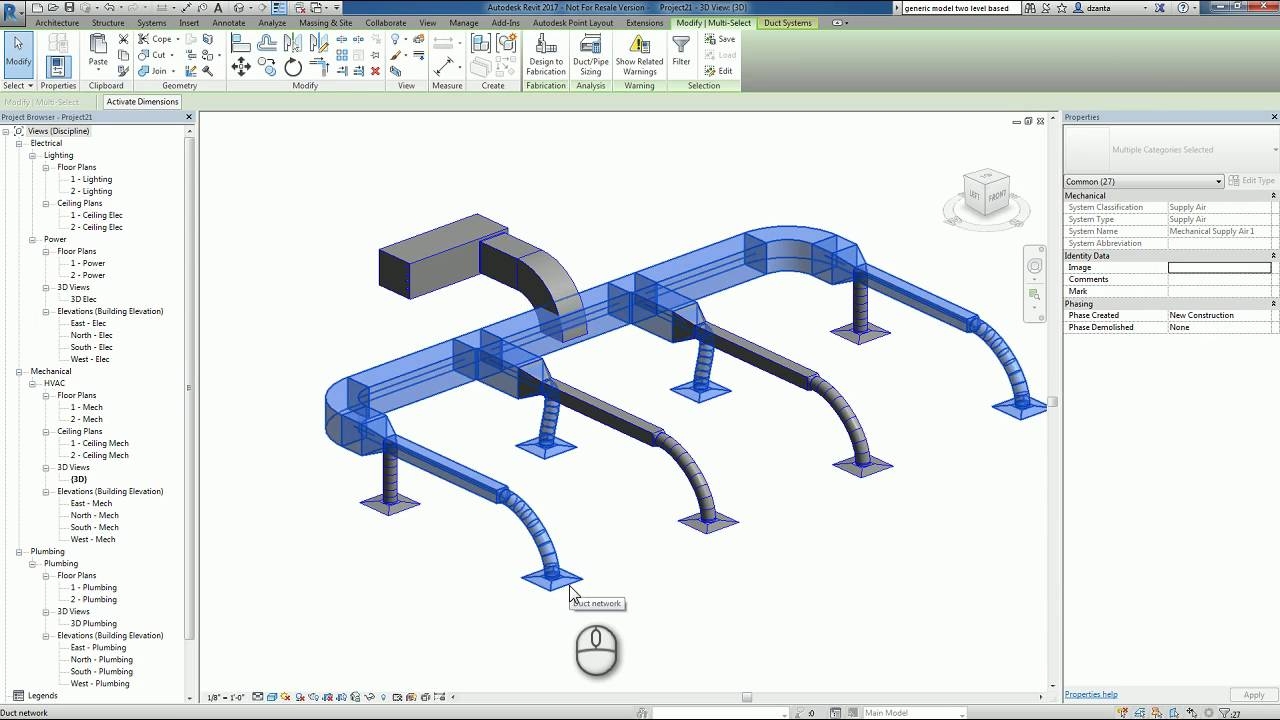

iSox Design Software

A unique iSox CAD design makes the precision system design a breeze.

Full installation manual & specialized tools

Extensive workflow pictures in the detailed installation instruction, along with proprietary tool (cable tightener) quickly turn a novice installer to Professional in no time.

Advanced Production

Advanced Production

Large scale laser automatic production line

Possessing the world’s unique automatic production lines Nanosox reaches the production capacity of 3.000.000 m2 per year

Global Top Advanced multi-head Laser Processing Center

Global Top Advanced multi-head Laser Processing Center

Precise processing technology of Nanosox system reaches the international top level with the global top advanced multi head laser processing center.

Large Scale and Full Range of Storage Leads to Shorter Lead Time

Large Scale and Full Range of Storage Leads to Shorter Lead Time

Full range of storage facilities, plus highly efficient production management system, shortens regular lead time to less than 15 days, an deven shorter for special orders.

World Leading Effect Testing Simulation Platform

World Leading Effect Testing Simulation Platform

All the finished products would be tested at the effect testing platform, which guarantees the zero-defect and completely accordant air distribution effect as per the design requirement

|

|

1. Y-inlet |

General Fittings

General Fittings

Usually single-layer or double-layer inlet fittings close the outer surface of the metal channel by means of belts and rivets. DurkeeSox®, on the other hand, with its double layer inlet fitting, only the first layer is installed in the metal duct, secured to the duct by means of a belt and concealed by the second layer, and is very easy to remove and wash.

End Cap

End Cap

Durkeesox uses an end cap, joins with duct by zipper, easier to change for washing or extend in the length direction.

Zipper Connection

Zipper Connection

Join among straight duct, fittings and components, like conventional used flange.

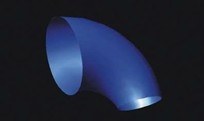

Elbow

Elbow

Standard centerline radius is 1,5 x Dia. The elbow consists of multiple gores, different curve angles per application requirement.

A-System Layout

General Location Layout

Low space layout: Make ductwork layout along Wall, beam, pole to save space and improve aesthetics. For workshop application, lay out ductwork along production line or densely occupied area to meet both requirements of production and occupants. For supermarket application, uniformly lay out the system perpendicular to shelves and parallel to light area.

High and Large space layout: To match return air, use straight duct as possible to improve indoor air distribution. For workshop layout shall be along production line, avoid equipment’s and travelling crane, meanwhile, consider directional air dispersion. For supermarkets, the layout is perpendicular to shelves or above main walkway. For sports place layout shall be around auditoria. For grid structure, layout ductwork inside it. For grid structure with berm, mount ductwork both sides along berm, both save space and convenience installation and maintenance.

General Location Aesthetics Design

The relation between duct diameter and aesthetics at the different installation height: Generally, the applicable duct diameter is larger when the installation is higher to reach a perfect combination of aesthetics and effect.

Arc Closed Design: The layout could be in arc, or closed round, Oval to match with architecture style for both more aesthetic appearance and uniform air dispersion.

Design to match with decoration: Mount half-round or Quarter-round duct against ceiling or open a groove on suspended ceiling then put Nanosox duct inside. For meshed suspended ceiling just mount ductwork above it.

Special Case Design

Temporary Location Design: Considering easy installation and dismantlement, track installation is mostly applied. To take reuse into account, maintain the same duct diameter and duct length as possible.

Anti-condensation design: Layout the ductwork along glass curtain or specially mount one or more ducts to easy condensation area.

System Layout

Use iSox design software, we could complete layout design and drawing work more easily and quickly.

B - Dimension Selection

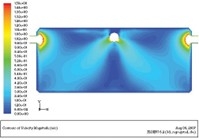

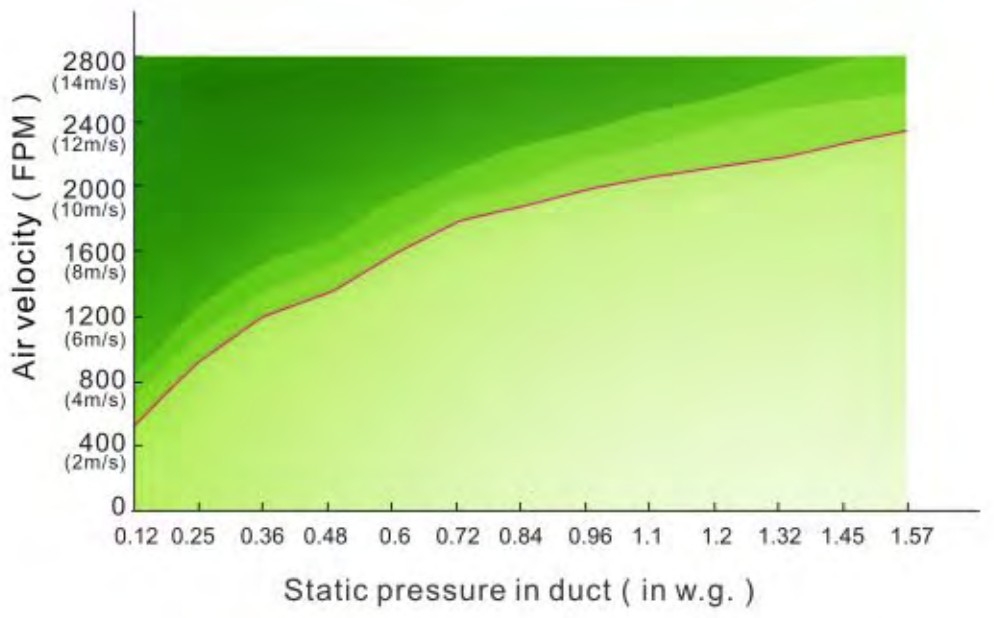

Nanosox system diameter selection is related to air velocity and static pressure in the duct , when the static pressure doesn't match the air velocity in the duct, the airflow in the duct will become turbulent which will affect the actual air dispersion and overall performance. Shown by left schematic illustrating relation between pressure, turbulence and air velocity that we obtained through an experiment

Nanosox system diameter selection is related to air velocity and static pressure in the duct , when the static pressure doesn't match the air velocity in the duct, the airflow in the duct will become turbulent which will affect the actual air dispersion and overall performance. Shown by left schematic illustrating relation between pressure, turbulence and air velocity that we obtained through an experiment

From the schematic, we could find when the air velocity is bigger, static pressure becomes smaller, the turbulence will be increasing (darker the coIour,bigger the turbulence),it is for sure that turbulence is related to the ratio of air velocity to static pressure in duct, the bigger the turbulence is. What is more, high air velocity could increase noise from system.+

A Nanosox system diameter utilizes mm as a spec unit starting at 152mm to 1828mm.The duct diameter is determined according to air volume and system inlet air velocity.

Calculation equation: g = v. π. 02/4

g: Air volume per duct system

v : System inlet air velocity

O : System duct diameter

Nanosox system inlet air velocity: to avoid system inlet turbelence and negative pressure.

Round straight duct less than 9 m/s Elbow less than 8 m/s

T connection less than 8 mls Large half round less than 8 mls

Half round less than 7 mls Rectangle half round less than 8,5 m/s

If the duct diameter is excessively big, installation space is not enough, it is advised to use rectangle duct or divide the system into several small ducts.

C - Air Pressure Design

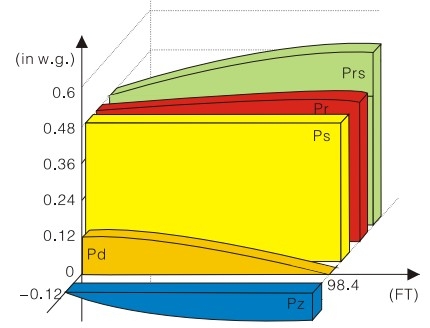

Pressure in a Nanosox system consists of static pressure, velocity pressure and resistance loss, the direct relation of static pressure regain, and resistance loss plays a key role. In most cases, static pressure regain is more than frictional resistance loss in straight duct. Result : Static pressure = inlet static pressure + static pressure regain — pressure loss

( Pr = Ps+Prs-Pz), the average pressure is the average of inlet static pressure and end static pressure. The principle is shown by left schematic.

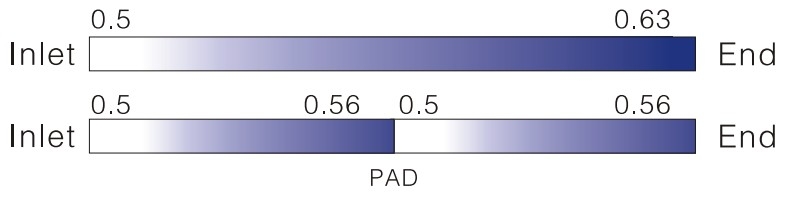

Based on abundant engineering experience, we believe that when pressure differences less than %10 of inlet static pressure, airflow along the duct is uniform. On the contrary, PAD pressure adjustment devices should be installed to balance the pressure in duct. Shown in below schematic, after balance, maximum pressure difference is in 25 Pa, less than %10 of inlet static pressure.

Inlet pressure of complicated system with multi ducts is according to resistance calculation of least favorable loop, meanwhile, consider air dispersion pressure, frictional and local pressure loss from main duct, branch duct.

D - Air Dispersion Design

Employing Nanosox patented design software specialized for fabric air dispersion system to maket he detailed design, that is to determine permeability of fabric, type, dimension, quantity and direction of orifice or nozzle, which is made by Nanosox engineering technology center.

Employing Nanosox patented design software specialized for fabric air dispersion system to maket he detailed design, that is to determine permeability of fabric, type, dimension, quantity and direction of orifice or nozzle, which is made by Nanosox engineering technology center.

According to cross section of height design we determine air throw and controlled area

Generally, we take the middle line of two adjacent ducts as the boundary, according to uniform layout principle. Based on actual project situation, in light of air volume from each duct and layout, divide the whole area, try to uniformly distribute the air volume as much as possible.

Determine Orifices direction

According to divided area, specify the direction of orifices and determine the number of orifice rows. According to air flow capacity, determine permeated air volume and air volume by orifices.

Determine size and rows of orifice

Generally, design is completed by patented specialized software iSox-manufactory and input into automatic production line for manufacturing. In addition, iSox software can help draw a standard construction plan of installation and automatically list a specification table for each portion of the system.