Coral S.P.A.'s experience and research led to the development of the Pulsotronic filter.

This modern high-pressure suction device is designed for the aspiration of dry grinding dust generated in plaster, composite materials, stone processing, marble processing and abrasive grinding processes.

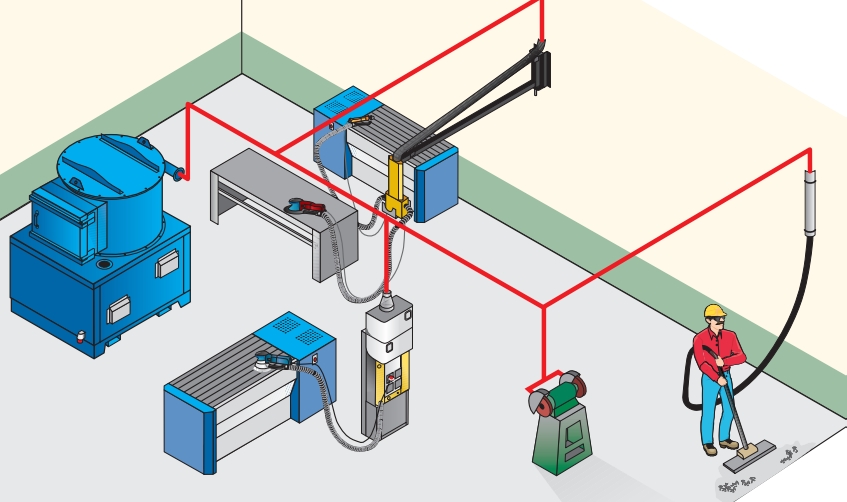

Its suitability for centrally located systems, its superior versatility where modular solutions are required, enables it to offer satisfactory solutions to meet any operational requirement.

For maximum operating efficiency, the Pulsotronic unit is equipped with a compressed air cleaning system managed by an advanced electronic control unit, which is able to self-adjust its settings according to the degree to which the filter cartridges are clogged. This optimized compressed air consumption extends its lifespan as it puts less mechanical strain on the filtering elements. The standard system also offers the possibility to monitor the clogging rate of the filters.

The Pulsotronic device can be equipped with a frequency inverter driven by a pressure compensator (optional) that can adjust the motor speed to optimize electricity consumption and suction efficiency under any conditions of use.

The unit's designers have focused their attention on noise control, placing the pump and cleaning system in a soundproofed compartment, thus keeping the noise emission level well below the limits required by current regulations (72 db).

As a result of the work carried out, the filter can be properly protected using devices provided in accordance with the ATEX 94/9/EC directive. If these are not required and installed, the user assumes full responsibility as defined in directive 99/92/EC (ATEX 137).

The ATEX version of the Pulsotronic filter is designed to operate in environments requiring a higher level of explosion protection than that required by the ATEX 94/9/EC directive. Its superior structural resistance is the result of finite element method product design (FEM ANALYSIS), compliance with the UNI EN 288-4 directive for welding areas and design consistency according to standard 97/23 (PED). These superior mechanical pressure resistance values allow the PULSOTRONIC filter to be used with ST2 class dusts.

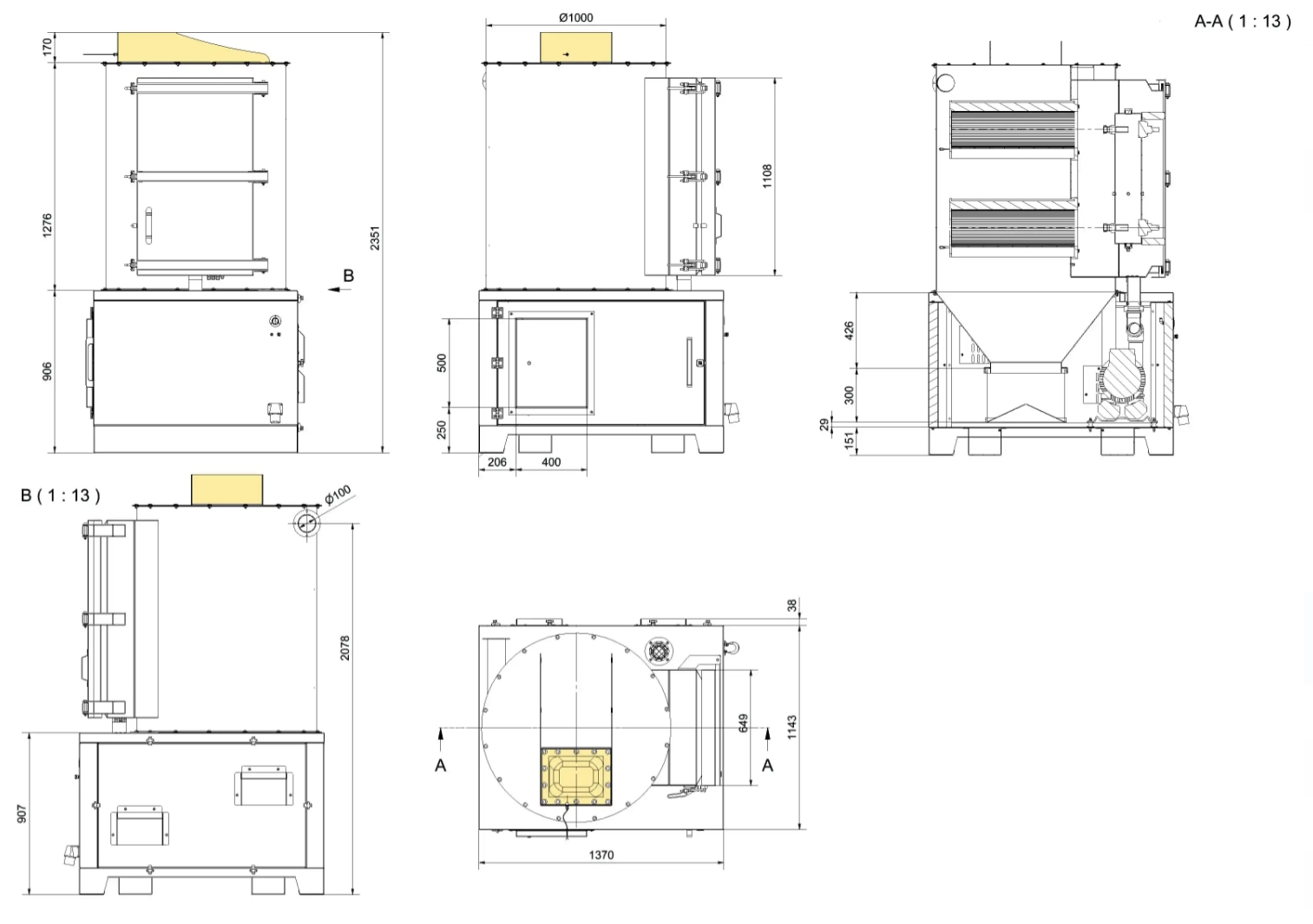

Technical Specifications

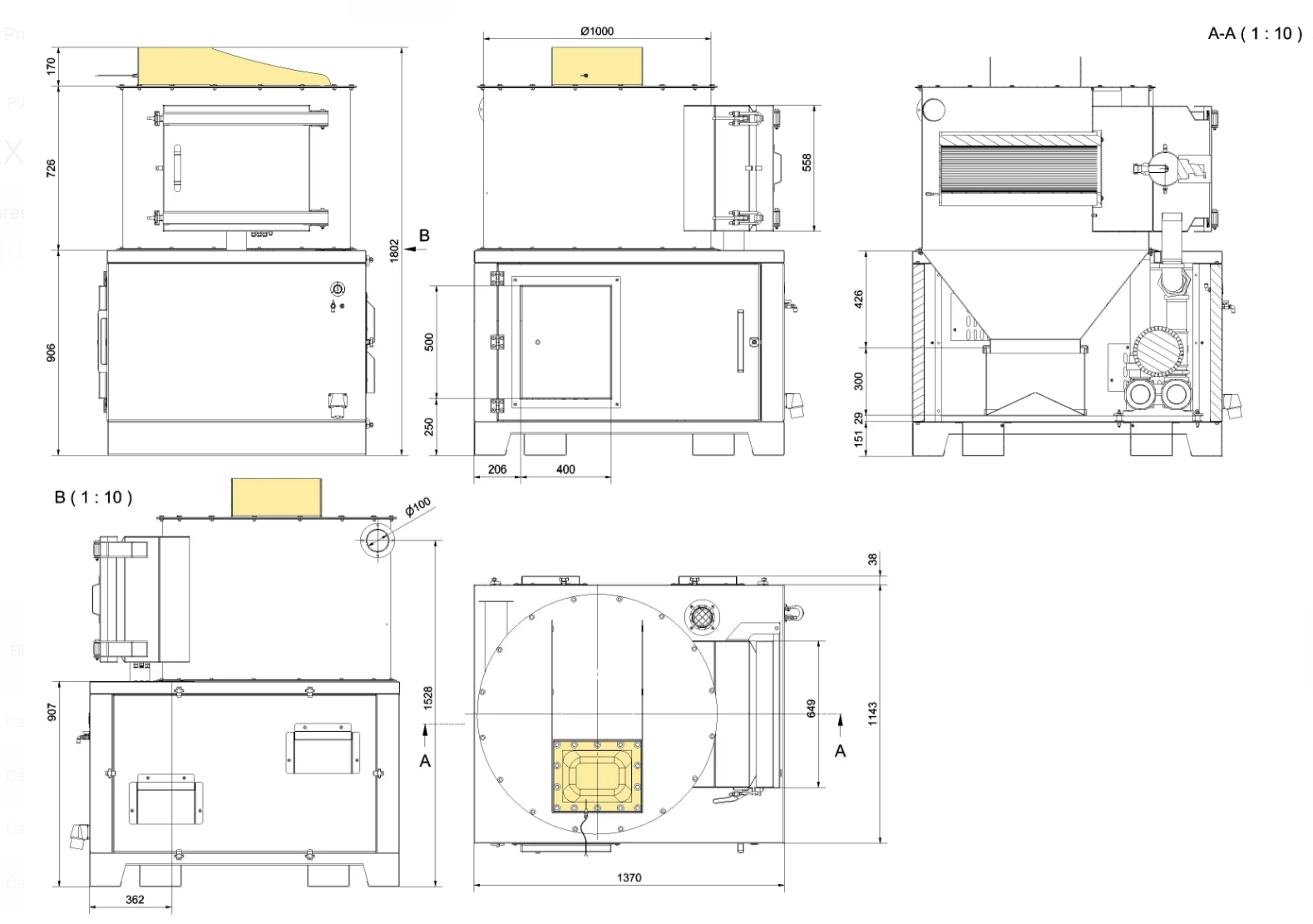

Installation Example

| PULSOTRONIC | 200 | 300 | 400 | 600 | 1000 | 200EX | 300EX | 400EX | 600EX | 1000 EX INDOOR/OUTDOOR |

| Filter Surface (m²/sq. m. ft) | 11/118 | 11/118 | 22/236 | 22/236 | 22/236 | 11/118 | 11/118 | 22/236 | 22/236 | 22/236 |

| Max. Air Flow (m³/h) | 260 | 350 | 420 | 650 | 1000 | 260 | 350 | 420 | 650 | 1000 |

| PUMP ELECTRIC POWER (KW) | 3 | 4 | 5,5 | 7,5 | 18,5 | 3 | 4 | 5,5 | 7,5 | 18,5 |

| Number of Cartridges | 1 | 1 | 2 | 2 | 2 | 1 | 1 | 2 | 2 | 2 |

| Cartridge DIMENSIONS | 0325 - H700 mm / 0325 - H700 mm | |||||||||

| BIA Class | USG, C (M) | USG, C(M) Aluminum Coating | ||||||||

| Max. Device Pressure (mbar) | 250 | 250 | 300 | 300 | 350 | 250 | 250 | 300 | 300 | 350 |

| Max. Working Pressure (Bar) | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| Valve Size / Number of Valves | 1" / 1 | 1" / 1 | 1" / 2 | 1" / 2 | 1" / 2 | 1" / 1 | 1" / 1 | 1" / 2 | 1" / 2 | 1" / 2 |

| Tank Air Capacity (Lt) | 7,3 | 7,3 | 14 | 14 | 14 | 7,3 | 7,3 | 14 | 14 | 14 |

| Dust Collection Capacity (Lt) | 30 | 30 | 30 | 30 | 100 | 30 | 30 | 30 | 30 | 100 |