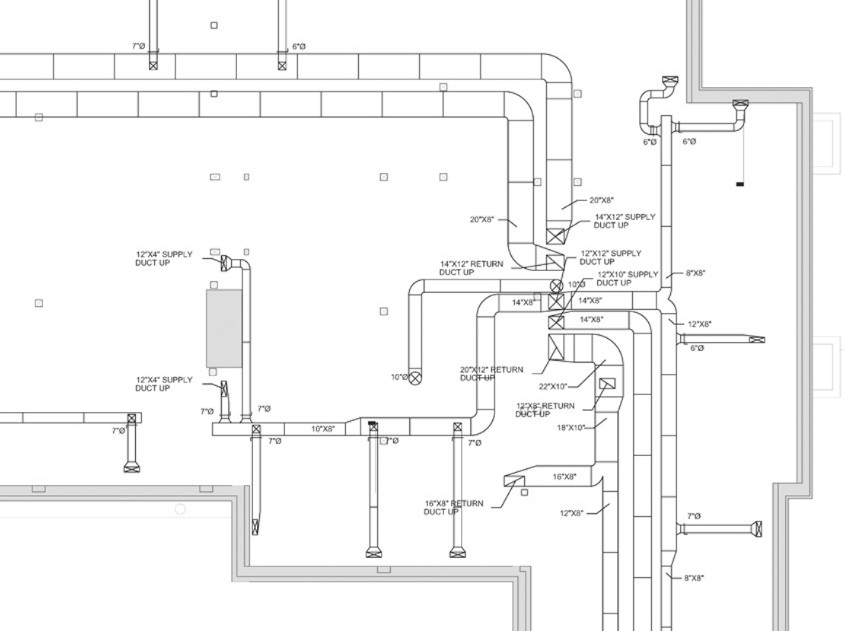

A-System Layout

General Location Layout

Low space layout: Make ductwork layout along Wall, beam, pole to save space and improve aesthetics. For workshop application, lay out ductwork along production line or densely occupied area to meet both requirements of production and occupants. For supermarket application, uniformly lay out the system perpendicular to shelves and parallel to light area.

High and Large space layout: To match return air, use straight duct as possible to improve indoor air distribution. For workshop layout shall be along production line, avoid equipment’s and travelling crane, meanwhile, consider directional air dispersion. For supermarkets, the layout is perpendicular to shelves or above main walkway. For sports place layout shall be around auditoria. For grid structure, layout ductwork inside it. For grid structure with berm, mount ductwork both sides along berm, both save space and convenience installation and maintenance.

General Location Aesthetics Design

The relation between duct diameter and aesthetics at the different installation height: Generally, the applicable duct diameter is larger when the installation is higher to reach a perfect combination of aesthetics and effect.

Arc Closed Design: The layout could be in arc, or closed round, Oval to match with architecture style for both more aesthetic appearance and uniform air dispersion.

Design to match with decoration: Mount half-round or Quarter-round duct against ceiling or open a groove on suspended ceiling then put Nanosox duct inside. For meshed suspended ceiling just mount ductwork above it.

Special Case Design

Temporary Location Design: Considering easy installation and dismantlement, track installation is mostly applied. To take reuse into account, maintain the same duct diameter and duct length as possible.

Anti-condensation design: Layout the ductwork along glass curtain or specially mount one or more ducts to easy condensation area.

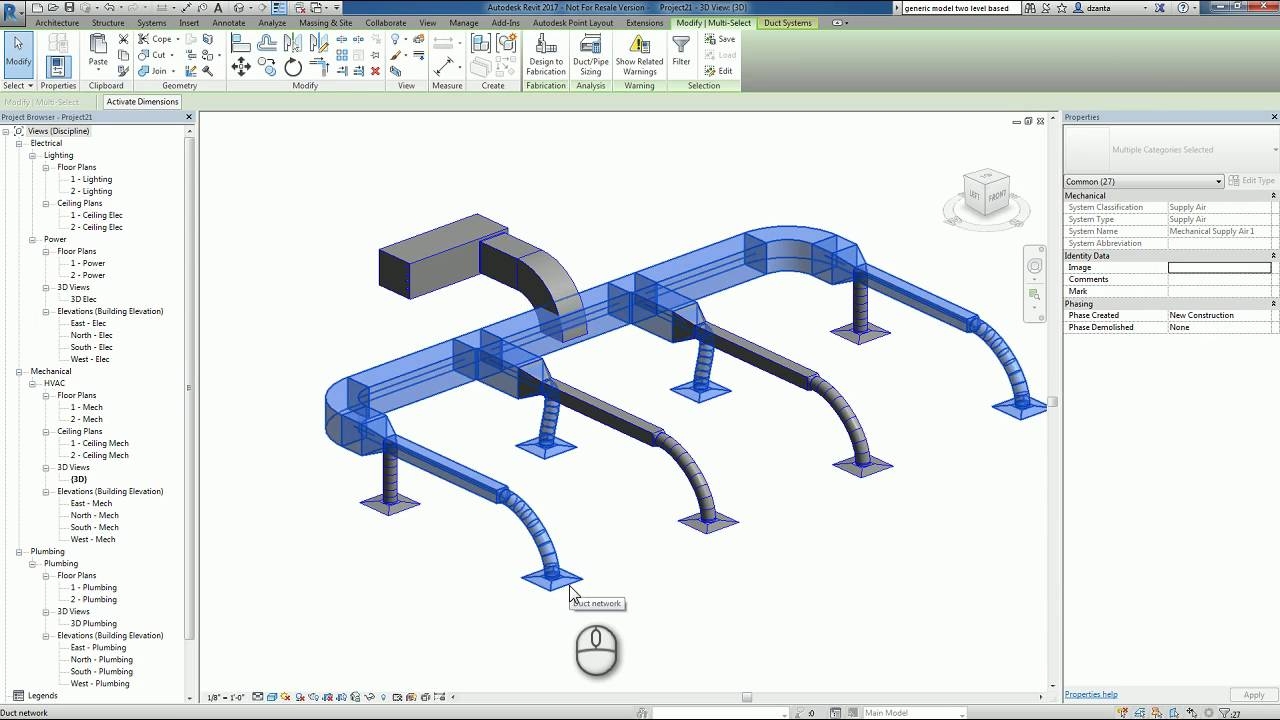

System Layout

Use iSox design software, we could complete layout design and drawing work more easily and quickly.

B - Dimension Selection

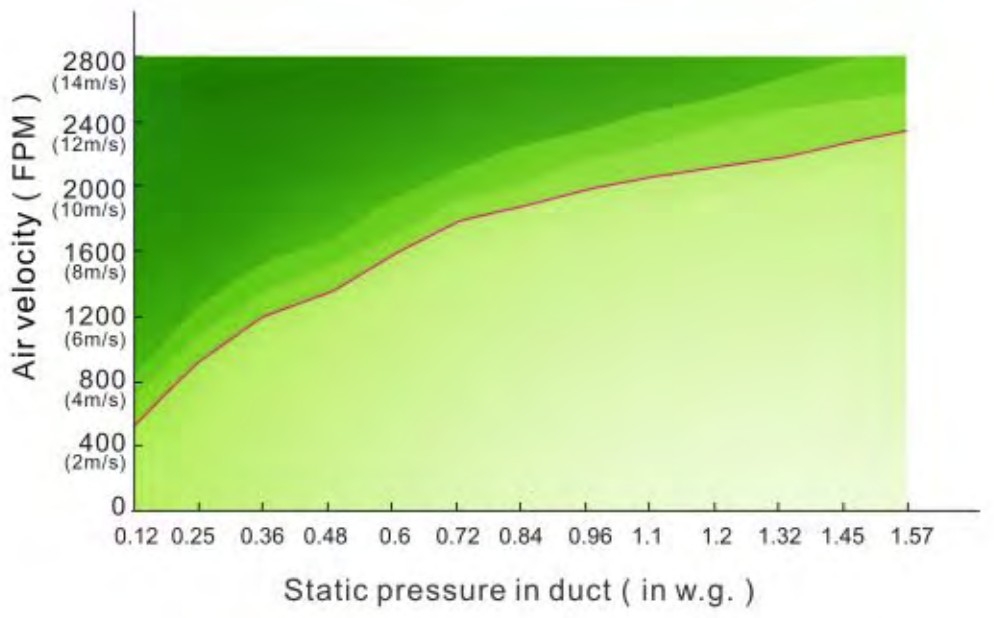

Nanosox system diameter selection is related to air velocity and static pressure in the duct , when the static pressure doesn't match the air velocity in the duct, the airflow in the duct will become turbulent which will affect the actual air dispersion and overall performance. Shown by left schematic illustrating relation between pressure, turbulence and air velocity that we obtained through an experiment

Nanosox system diameter selection is related to air velocity and static pressure in the duct , when the static pressure doesn't match the air velocity in the duct, the airflow in the duct will become turbulent which will affect the actual air dispersion and overall performance. Shown by left schematic illustrating relation between pressure, turbulence and air velocity that we obtained through an experiment

From the schematic, we could find when the air velocity is bigger, static pressure becomes smaller, the turbulence will be increasing (darker the coIour,bigger the turbulence),it is for sure that turbulence is related to the ratio of air velocity to static pressure in duct, the bigger the turbulence is. What is more, high air velocity could increase noise from system.+

A Nanosox system diameter utilizes mm as a spec unit starting at 152mm to 1828mm.The duct diameter is determined according to air volume and system inlet air velocity.

Calculation equation: g = v. π. 02/4

g: Air volume per duct system

v : System inlet air velocity

O : System duct diameter

Nanosox system inlet air velocity: to avoid system inlet turbelence and negative pressure.

Round straight duct less than 9 m/s Elbow less than 8 m/s

T connection less than 8 mls Large half round less than 8 mls

Half round less than 7 mls Rectangle half round less than 8,5 m/s

If the duct diameter is excessively big, installation space is not enough, it is advised to use rectangle duct or divide the system into several small ducts.

C - Air Pressure Design

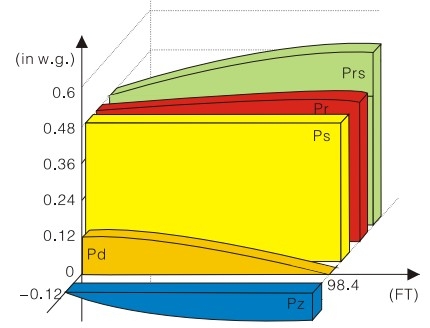

Pressure in a Nanosox system consists of static pressure, velocity pressure and resistance loss, the direct relation of static pressure regain, and resistance loss plays a key role. In most cases, static pressure regain is more than frictional resistance loss in straight duct. Result : Static pressure = inlet static pressure + static pressure regain — pressure loss

( Pr = Ps+Prs-Pz), the average pressure is the average of inlet static pressure and end static pressure. The principle is shown by left schematic.

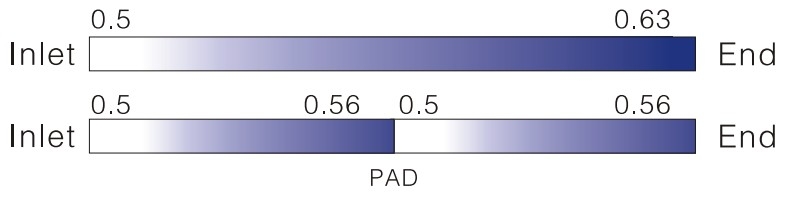

Based on abundant engineering experience, we believe that when pressure differences less than %10 of inlet static pressure, airflow along the duct is uniform. On the contrary, PAD pressure adjustment devices should be installed to balance the pressure in duct. Shown in below schematic, after balance, maximum pressure difference is in 25 Pa, less than %10 of inlet static pressure.

Inlet pressure of complicated system with multi ducts is according to resistance calculation of least favorable loop, meanwhile, consider air dispersion pressure, frictional and local pressure loss from main duct, branch duct.

D - Air Dispersion Design

Employing Nanosox patented design software specialized for fabric air dispersion system to maket he detailed design, that is to determine permeability of fabric, type, dimension, quantity and direction of orifice or nozzle, which is made by Nanosox engineering technology center.

Employing Nanosox patented design software specialized for fabric air dispersion system to maket he detailed design, that is to determine permeability of fabric, type, dimension, quantity and direction of orifice or nozzle, which is made by Nanosox engineering technology center.

According to cross section of height design we determine air throw and controlled area

Generally, we take the middle line of two adjacent ducts as the boundary, according to uniform layout principle. Based on actual project situation, in light of air volume from each duct and layout, divide the whole area, try to uniformly distribute the air volume as much as possible.

Determine Orifices direction

According to divided area, specify the direction of orifices and determine the number of orifice rows. According to air flow capacity, determine permeated air volume and air volume by orifices.

Determine size and rows of orifice

Generally, design is completed by patented specialized software iSox-manufactory and input into automatic production line for manufacturing. In addition, iSox software can help draw a standard construction plan of installation and automatically list a specification table for each portion of the system.