The HT humidifier is a compact, cabinet-style unit compatible with all water types (tap, softened, deionized, reverse osmosis) and numerous dispersion options. Installation is a snap - just attach the frame to a supporting structure and connect electrical and water services. Available matching Space Distribution Units disperse steam with no visible vapor trail, making Humidi-tech ideal for use in finished spaces.

HT Features

• Capacity from 2.7 to 46 kg/h, link up to 16 units for capacity up to 740 kg/h

• Disperses steam through ductwork with dispersion tubes or panels, or directly into a room with a Space Distribution Unit (SDU) mounted remotely or on top of the HT

• On/off or proportional control ability.

• Control to ± 3% RH

• Electronically monitored water level ensures safe and reliable operation

• End-of-season auto drain minimizes microbial growth

• Interoperability allows communication with building automation systems via Modbus or with optional BACnet or LonTalk protocols

• Softened water significantly reduces maintenance requirements.

• User-adjustable water skimmer skims off floating minerals

• Controller-operated drain and flush removes precipitated minerals from evaporating chamber

Capacity and Electrical Specification

| Model | Maximum Electrical Power (kW) | 230V | 3 Phase 230V | Shipping Weight (kg) | Operating Weight (kg) | Code | ||

| Steam Capacity (kg/h) |

I Max (A) | Steam Capacity (kg/h) |

I Max (A) | |||||

| HT 2 | 2 | 2,5 | 8 | 2,7 | - | 37 | 44 | 40122002 |

| HT 4 | 4 | 5 | 16 | 5,4 | 8,7* | 37 | 44 | 40122004 |

| HT 6 | 6 | 7,5 | 24 | 8,2 | 13,0* | 41 | 56 | 40122006 |

| HT 8 | 8 | 10 | 31,9 | 10,9 | 17,3* | 41 | 56 | 40122008 |

| HT 10 | 10 | 12,5 | 39,9 | 13,6 | 15,2* | 43 | 64 | 40122010 |

| HT 12 | 12 | 15 | 47,9 | 16,3 | 17,3 | 43 | 64 | 40122012 |

| HT 14 | 14 | - | - | 17,5 | 20,2 | 43 | 64 | 40122014 |

| HT 16 | 16 | - | - | 21,8 | 23,1 | 43 | 64 | 40122016 |

| HT 21 | 21 | - | - | 28,6 | 30,3 | 44 | 70 | 40122021 |

| HT 25 | 25 | - | - | 34 | 36,1 | 44 | 70 | 40122025 |

| HT 30 | 30 | - | - | 40,9 | 43,3 | 47 | 72 | 40122030 |

| HT 34 | 34 | - | - | 46,2 | 49,1 | 47 | 72 | 40122034 |

Principal of operation

1. When the system is first activated, the fill valve opens, and the evaporating chamber fills with water to the operating level.

2. On a call for humidity, the heating elements are energized,

causing the water to boil. The fill valve opens and closes as needed to maintain the operating water level

3. During refills in tap/softened water systems, a portion of the surface water is skimmed off, carrying away precipitated minerals. DI/RO water systems (systems using deionized water or water that has been treated using reverse osmosis) do not require skimming.

4. Steam created in the evaporating chamber flows through vapor hose or piping to the dispersion assembly, where it is discharged into the airstream

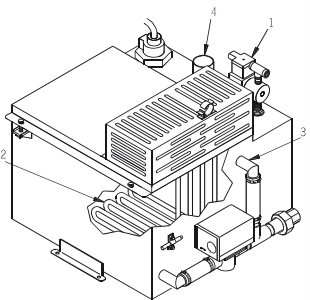

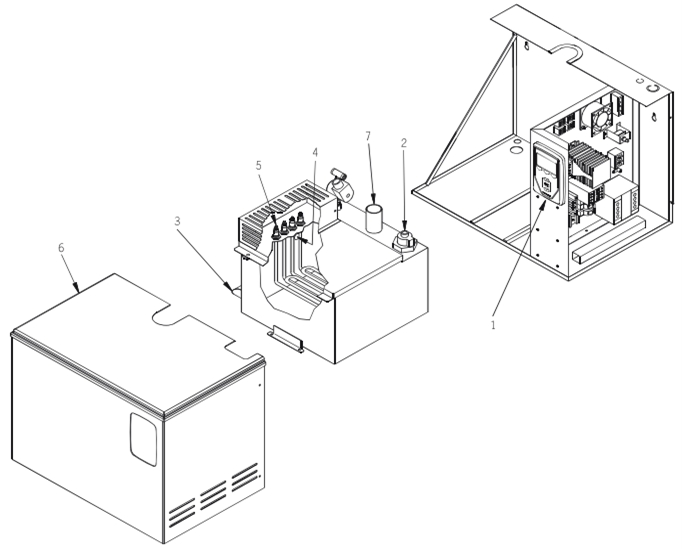

HT Components

1. Vapor-Logic 4 Controller: Vapor-logic4 controls all humidifier functions and can connect to a building automation system via Modbus or optional BACnet MS/TP or LonTalk

2. Water Level Control: Tap or softened water systems control water levels electronically using a three-rod probe. DI/RO water systems control water levels using a float valve and low-water cutoff switch.

3. Drain: Duration and frequency of draining are user adjustable. To avoid possible stagnant water and microbial growth, the humidifier automatically drains if there is no call for humidity after a user defined time (72-hour default).

4. Water skimmer/overflow port: In tap/softened water systems, the water skimmer reduces surface minerals in the evaporating chamber. Skimming occurs each time the humidifier fills. The skim time duration is user adjustable. DI/RO water systems do not require skimming. In DI/RO systems, the skimmer port functions as an overflow port.

5. Heating Element: Low-watt-density Incoloy-sheathed heating elements ensure operation for many seasons. Constant expansion and contraction of heating elements shed mineral scale. In the unlikely event of heater failure, heating elements can be removed easily.

6. Removable cover: A removable cover allows easy access to the evaporating chamber, electrical connections, and drain

7. Steam outlet: Steam generated in the humidifier rises through the steam outlet and travels to the dispersion assembly through vapor hose or piping

8. Temperature sensor (not shown): Mounted on the evaporating chamber, this sensor enables Over-temperature protection, freeze protection, Preheating, allowing rapid response to a call for humidity