What does ATEX mean?

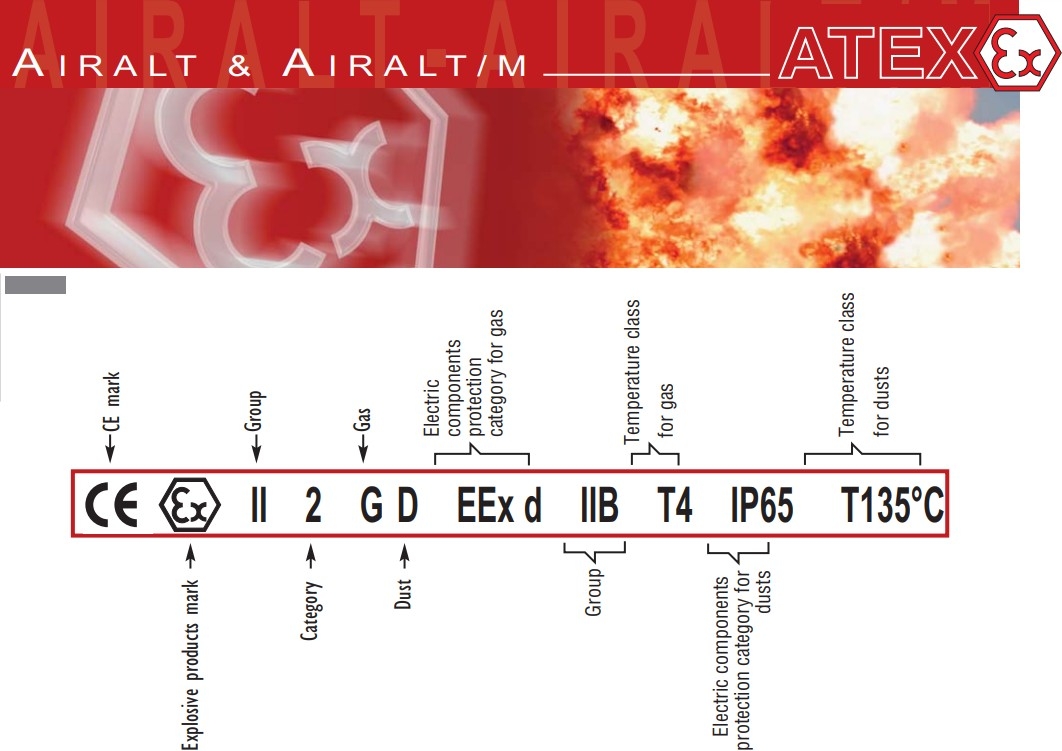

ATEX is an abbreviation of the French words "ATmospheres EXplosives". This term covers all areas of equipment used in potentially explosive atmospheres where dusts (denoted by D) and gases (denoted by G) are present.

What does "equipment" mean?

As defined in Directive 2014/34/EU, the term "equipment" includes any machinery, materials, central or mobile devices, control elements, hand tools, detection, and energy conversion of detection and extinguishing systems, as well as equipment that may cause an explosion due to the potential ignition sources they contain, as well as any machinery, materials, central or mobile devices, control elements, hand tools, detection and extinguishing systems used together or alone for production.

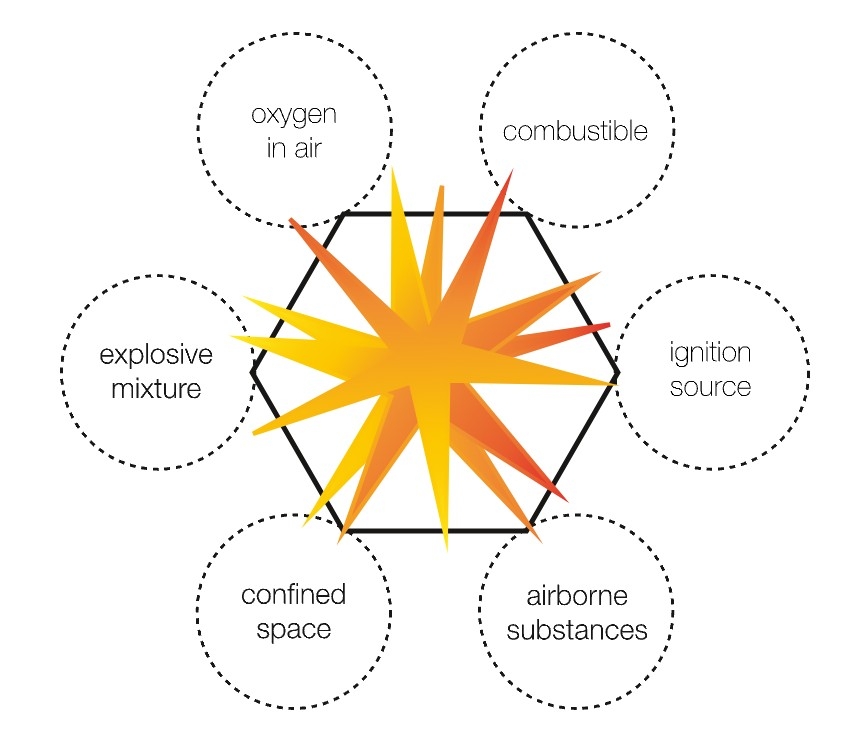

What is an "Explosive Atmosphere"?

Classification of powders according to established parameters

Explosive powders are divided into 4 classes according to their Kst values. The explosion categories of powders according to their kst values are given in the table below.

| Explosion Class | Kst [ bar*m/s ] | Explosion Type | |

| St0 | 0 | No | |

| St1 | 0< | 200< | Slim |

| St2 | 200< | 300< | Strong |

| St3 | 300< | Very powerful | |

Classification of Explosive Zones

| Danger Zone | Gases, Vapors, Mists (G) | Powders (D) |

| The zone where the explosive gas mixture is constantly present | ZONE0 | ZONE 20 |

| Zone where explosive gas mixture is likely to occur | ZONE 1 | ZONE 21 |

| An area where there is normally no explosive gas mixture, but if there is, it will not remain for a long time | ZONE2 | ZONE 22 |

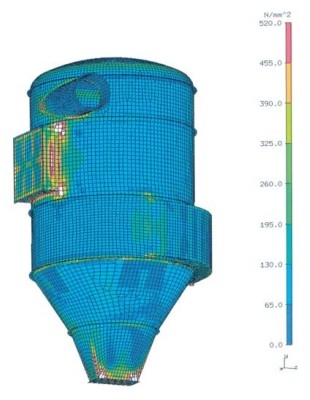

AIRALT 360 FEM ANALYSIS

|

|

STUDIES HAVE SHOWN THAT THE FILTER CAN BE PROPERLY PROTECTED USING DEVICES THAT COMPLY WITH ATEX 94/9/EC AND EN 1127-1. IN THE EVENT THAT SUCH PROTECTIVE DEVICES ARE NOT ORDERED AND/OR INSTALLED, THE USER SHALL BE LIABLE IN ACCORDANCE WITH 99/92/EC (ATEX 137). |